These powerful tools have turned out to be a must-have in the world of product design: Finite Element Analysis, FEA; and Computational Fluid Dynamics, CFD. Which do benefit the most from such advanced techniques?

·

Aerospace and automotive

components

·

Consumer electronics

·

Industrial equipment

·

Medical devices

Aerospace and automotive components

The aerospace and automotive industries are highly innovative

where safety and performance would be put into a non-negotiable area. CFD Smoke Analysis of air flowing over wings

or even bodies of cars improves aerodynamics and efficiency in terms of fuel

consumption. FEA testing on structural integrity is also very important in all

components, such as wings, chassis, and others from the engine.

Consumer electronics

For consumer electronics, where thermal management and

durability are key factors, FEA and CFD play a huge role. In that way, the

overheating of the device is avoided. Renewtherm Engineering helps evaluate how

electronics can survive drops or pressure without breaking.

Industrial equipment

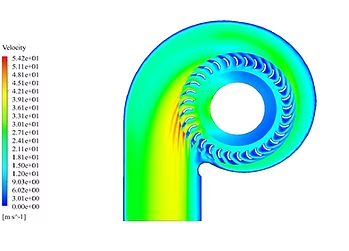

Heavy machinery, heavy plant equipment-including pumps,

turbines, and compressors-and all similar equipment are significantly aided by

these analyses. Data

Center CFD Analysis optimizes the efficiency and

performance of the flow path.

Medical devices

The stents and surgical instruments must perform under flawless

conditions. CFD analysis can simulate blood flow around the stents so that

patients are assured of safe and effective products, while Structural Analysis FEA ensures

that the surgical tools meet the standards of strength and durability.

Enormous benefits can be acquired by products in various industries with CFD and FEA analysis. Design creation will be much safer, more efficient, and more reliable to meet the demands of the present market with these tools.

For more information, you can visit our website https://www.renewtherm.com/ or call us at +971-506180620/+91-9884791650

No comments:

Post a Comment