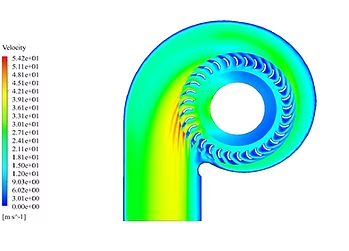

The models consider a wide range of variables that affect airflow and temperature. They help make exact designs, even for installations in quite limited areas. A comfort analysis and product validation can be achieved by HVAC CFD Analysis, which considers factors like sunshine, room layout, and the placement of air vents around furniture. The objective is to determine the optimal air circulation solutions for the project area.

Why a CFD Analysis?

CFD has been around for a while and is used by many sectors.

Rather than spending a fortune on costly real-world testing and validation, you

can save a lot of money by investing in virtual CFD analysis. Plus, there's no

need to worry about the potentially expensive costs of making on-site

adjustments to the HVAC system after installation. You can find the best

airflow for each room by doing a computational fluid dynamics (CFD) simulation

early in the HVAC design process, yielding much helpful knowledge.

What’s the Difference between FEA and CFD?

Comparing High Quality CFD & FEA Analysis is a challenging

task. Traditional structural problems are well-suited to solving partial

differential equations made possible by Finite Element Analysis (FEA). These

approaches are better adapted to tackle fluid flow problems and comprise

computational fluid dynamics (CFD). The good news is that FEA can help with

some CFD errors!

Conclusion

For product design and computer-aided engineering (CFD & FEA) analysis, Renewtherm Engineering is the go-to engineering consultancy for a wide range of sectors. We want to enhance product performance by streamlining the design and analysis process to make it lighter and more energy-efficient. We can significantly lessen our impact on the planet through creative thinking and the creation of environmentally friendly goods.

For more information, you can visit our website https://www.renewtherm.com/

or call us at +971-506180620/+91-9884791650

No comments:

Post a Comment