In detail, the designing of a pressure vessel is very precise in steps. Critical components operate high with the worst of environments they deserve nothing less than absolute reliance on safety and efficiency, making CFD and Finite Element Analysis vital tools in the transformed engineering of pressure vessel designing; from its capability for virtual testing or even virtual refinement or simulation to achieve designs that are innovative and efficient.

·

Improving safety

·

Efficiency improvement

·

Saving time and reducing costs

Improving safety

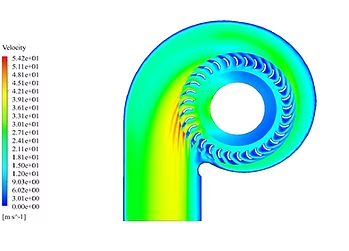

CFD helps in identifying high-pressure regions, turbulent areas,

or uneven fluid distribution that, over time, may strain a vessel. On the other

hand, FEA looks at structural integrity. Renewtherm Engineering points

out weak points like welds or corners where stress likes to accumulate.

Strengthening these points ensures that the vessel will perform both within

normal and extreme operating conditions.

Efficiency improvement

You would be surprised to know that Pressure Vessel CFD & FEA Analysis now appears as the

element of ensuring this with efficient fluid flow along with efficient heat

transfer. By it, pressure drops could reduce within a vessel for steady operational

outputs without loss of potential energies in vessels used on important systems

where the efficiency of systems at a priority is on prime consideration.

Saving time and reducing costs

One of the major advantages of using CFD and FEA is that they

can save time and money. Conventionally, pressure vessel design had to rely on

a great deal of physical prototypes, which could be time-consuming and

expensive to build and test. With

CFD & FEA Simulation, multiple design

iterations can be tested virtually.

For more information, you can visit our website https://www.renewtherm.com/ or call us at +971-506180620/+91-9884791650

No comments:

Post a Comment