Computational Fluid Dynamics

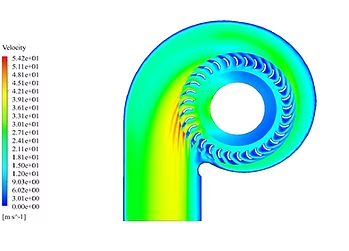

(CFD) has transformed smoke and gas modeling. Intelligent algorithms and

programs model smoke's movement, distribution, and interactions with objects in

CFD. These models are crucial in design, fire safety, and environmental

investigations. Find out how CFD smoke research works and its science.

Simulating

Smoke Behavior

CFD Smoke

Analysis predicts smoke behavior using fluid

dynamics. Models help engineers understand smoke spread. These data help design

ventilation, airflow, and fire protection systems. CFD shows us scenarios that

are risky or difficult to duplicate. It helps us understand smoke movement in

tight or open spaces.

Fluid

Mechanics and Smoke Interaction

CFD smoke analysis examines

smoke's interactions with air and objects. Using temperature, pressure, and

wind, CFD simulates smoke particle movement, collision, and spread. These

interactions help plan smoke management and evacuation pathways for buildings,

tunnels, and workshops. The precision of CFD helps professionals design smoke

control devices for any situation.

Applications

across Industries

CFD Smoke Analysis benefits fire safety, aerospace, automotive, and entertainment industries. In aircraft, CFD predicts smoke behavior during an accident, improving flight systems. Car developers use it to enhance exhaust systems. CFD creates realistic smoke effects in movies and games, improving immersion.

Structural

Analysis FEA

Structural Analysis

FEA is a computer technique that models and evaluates

building behavior under different stresses and circumstances. It helps

engineers optimize designs, stay safe, and predict material and building

issues.

Summary

CFD smoke studies show how

smoke travels and behaves, making it easier to comprehend and forecast. This

technology provides insights that improve fire safety, industrial design, and

more. Renewtherm is the best engineering consultancy.

For

more information, you can visit our website https://www.renewtherm.com/

or call us at +971-506180620/+91-9884791650